Wieland Textiles has three core activities which are the purchase of collected textiles, the sorting of collected textiles in two main streams (reusable clothing and textile materials, and the marketing and sale of sorted textiles.

The purchasing of used textiles is done in order to sort it for reuse as a product (second-hand clothes) or as a material (such as cleaning clothes). The materials are cleaned up by removing household waste, pillows and duvets, paper and other kinds of waste. Subsequently, pre-sorting takes place: the bags are open, several kinds of textile products are sorted and waste fractions are removed. The remaining wet clothes are partly dried mechanically and added to the original. The unusable wet clothes are sorted with the remaining waste fractions in a container that is transported by a waste processing company once a month to the nearest waste incineration plant.

Wieland Textiles, together with a supply chain software developer (Retail Experts) founded Textiles2Textiles (https://textiles2textiles.com/) an organization focused on textile reuse in its ultimate form. Their aim is to deploy technological innovations in order to literally reuse every garment and fiber.

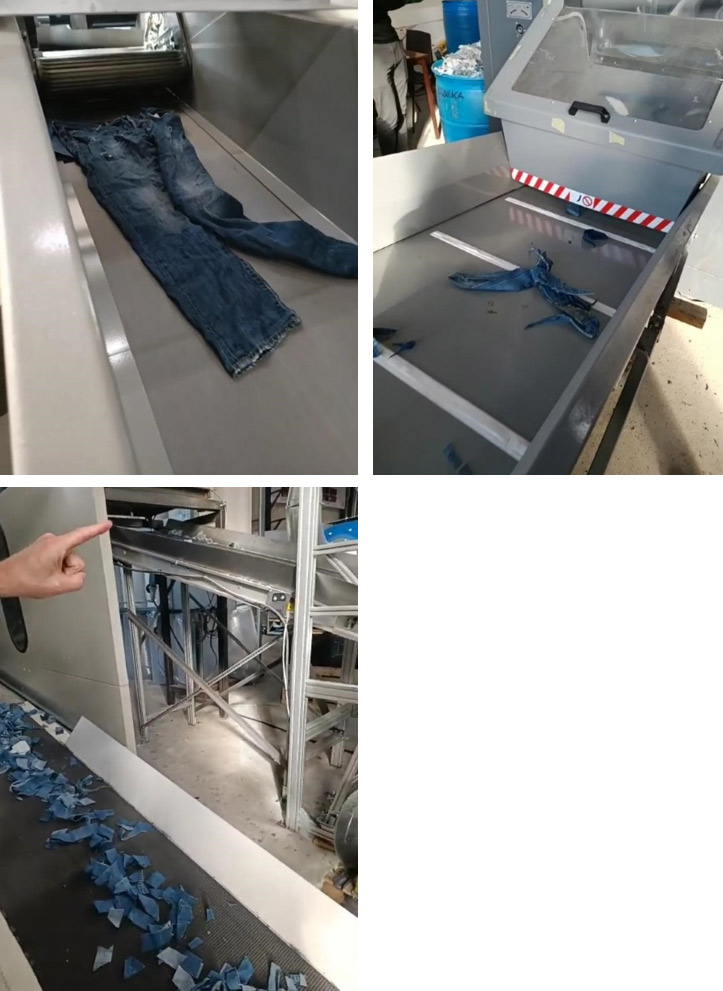

Theis main product is PCC (Post Consumer Clippings), a unique solution that is used as feedstock for the textile manufacturing industry.

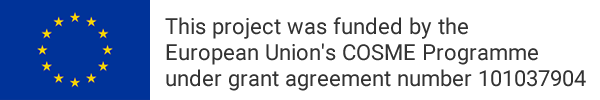

The process goes from removing contamination from the textiles to the simple sorting and the fiber sorting, then the cutting and cleaning, and finally the supplying recyclers.